SLS 3D Printing Service

Selective Laser Sintering is a 3D printing process that produces a highly precise and accurate part. It can be used for a variety of industries, including automotive, aerospace, and medical.

What is SLS 3D printing?

SLS 3D printing is perfect for parts that need to be precise and accurate, while maintaining strength and durability properties. It is available for our nylon and polyurethane materials.

The process of SLS printing involves layering a polymer powder and solidifying it with a laser and binding agent. The part is them built up layer-by-layer until the final product is completed.

SLS is a cost-effective production method. It is capable of producing large parts and parts with complex geometries.

Visit our home page for a complete list of our materials.

SLS 3D printer capabilities

Maximum build size |

Standard lead time |

Tolerance |

Layer height |

Minimum feature size |

| 340mm x 340mm x 600mm (Nylon) | 6 business days |

(X,Y): +\- 0.300mm or 100mm +\- 0.3% (Z): +\- 0.400mm or > 100mm +\- 0.4% |

120 μm | 1 mm |

| 700mm x 580mm x 380mm (Polyurethane) | 12 business days |

(X,Y): +\- 0.3mm or 100mm +\- 0.3% (Z): +\- 0.4mm or 100mm +\- 0.4% |

120 μm | 1 mm |

SLS 3D printing materials

Our SLS services are available for a wide variety of materials

Material |

Default Color |

Resolution |

Weaknesses |

Strengths |

Applications |

| Nylon PA 2200 | white | 120 µm | slightly higher cost | superior strength | complex geometries |

| Nylon PA 12 | recycled white | 120 µm | possible defects | cheaper cost | prototypes |

| Polyurethane | white | 120 µm | longer lead time | flexible material | medical braces |

Post-processing for SLS

We offer multiple finishing options for SLS printed pieces.

Raw- No finish applied, as machined

Polished- Part is tumbled and then shot-peened, resulting in a very smooth surface

Vapor polished- Part is sealed in a chamber and coated with acetone vapor to smooth surface, resulting in a polished surface

You can also have your SLS parts dyed to any color you like by selecting the color in our quote engine.

How SLS stacks up against other 3D printing technologies

Materials |

Price |

Strengths |

Max. part size |

Layer thickness |

Min. feature size |

|

SLM |

Aluminum, 316L Stainless Steel, 17-4 Stainless Steel | $$$ | Metal parts | 400mm x 320mm x 320mm | 50µm – 200µm | 1 mm |

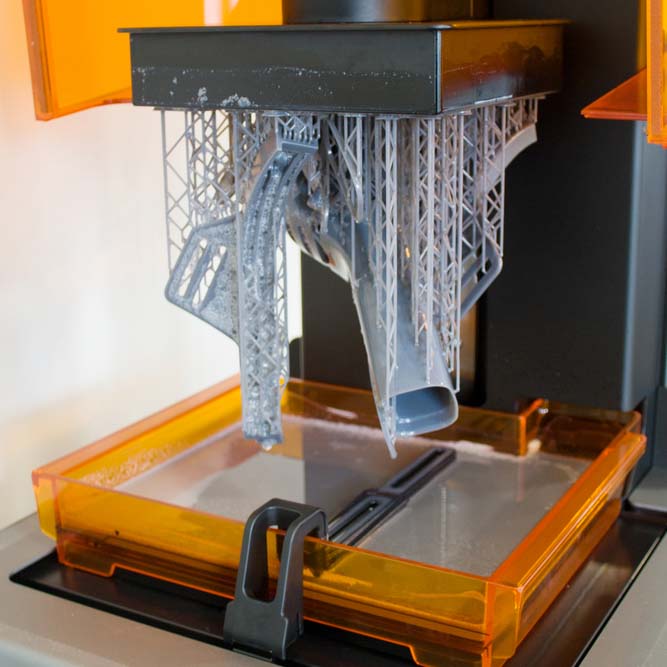

SLA |

Proto Plus, WaterTight, Smooth GP, Transparent Plus, Tough Plus, High Temp TS, Imagine Black | $$ | Smooth surface finish | 1380mm x 680mm x 480mm | 50µm – 200µm | 1 mm |

SLS |

Nylon PA12, Nylon PA2200, Thermoplastic Polyurethane (TPU) | $$$$ | High precision |

|

120 µm | 1 mm |

MJF |

Nylon PA12, Nylon PA11, GLass Filled Nylon, Polypropylene, Full Color(CBPA12) | $ | Strong structures | 380mm x 280mm x 380mm | 80 μm | 1 mm |

Why should you choose SLS 3D printing?

SLS printing is a great option for any project. It can be done with materials that are exceptionally strong or that are capable of producing a flexible part, depending on your needs. It is also an environmentally-friendly manufacturing process.

We have high standards for SLS 3D printing

With JawsTec, every order is backed by our quality assurance policy. Each part will meet your standards and fulfil the needs of your project.

Read this article for more information on our quality and return policies.

Advantages and drawbacks of SLS 3D printing

Advantages

- Superior strength of structures and geometries

- High precision of parts

- Design guidelines allow for highly customized designs

- No supports needed for printing

Drawbacks

- PA12 material can result in surface defects due to its recyclable nature

- Slightly more expensive than other printing processes

- Occasional longer lead-time as opposed to other materials

Designing files for SLS printing

There are a number of rules you will want to keep in mind when designing your CAD files for SLS printing:

- Save cost and time by minimizing mass volume and wall thickness wherever possible

- Remember our tolerance guidelines, use symmetric design tolerances

- Rounded corners generally work better than sharp ones, saves material and improves flow of force

- Optimize parts for powder removal in post processing

- Design with a minimal loose connection distance of 0.1 mm

More resources for SLS 3D printing

Visit the links on the right to learn more about SLS 3D printing! Or, you can visit our blog to explore other helpful articles and information.

Want to learn more about SLS?

Our Other 3D printing processes

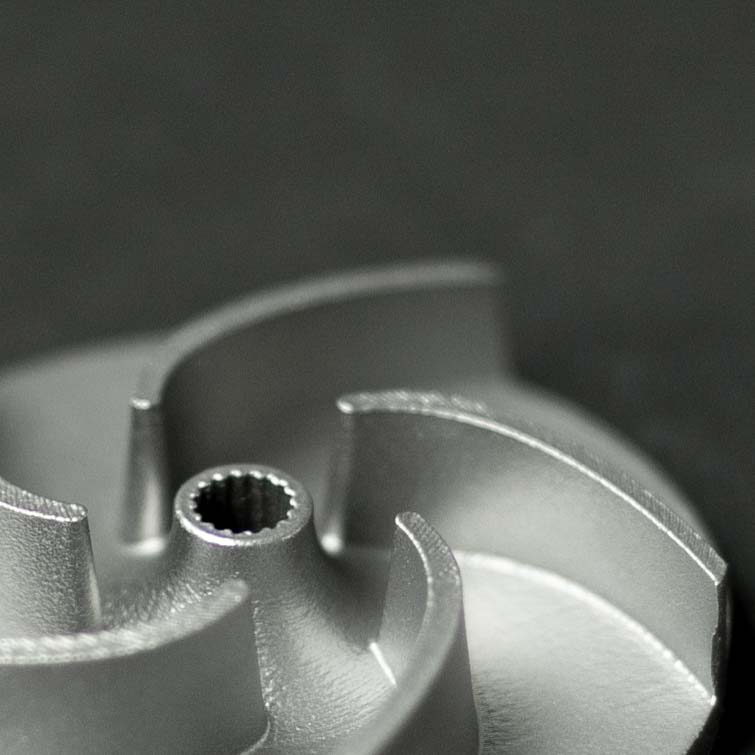

SLM

Need to print some metal parts? We’ve got you covered with our SLM printing technology.

- Lightweight metal parts

- Highly customizable metal parts

SLA

Looking for another option to 3D print your parts? Check out the SLA process

- Dimensional accuracy

- Smooth surface finishes

MJF

Want a slightly cheaper 3D printing option than SLS? Take a look at the MJF process.

- Cost-effective process

- Watertight structures