SLA 3D Printing Service

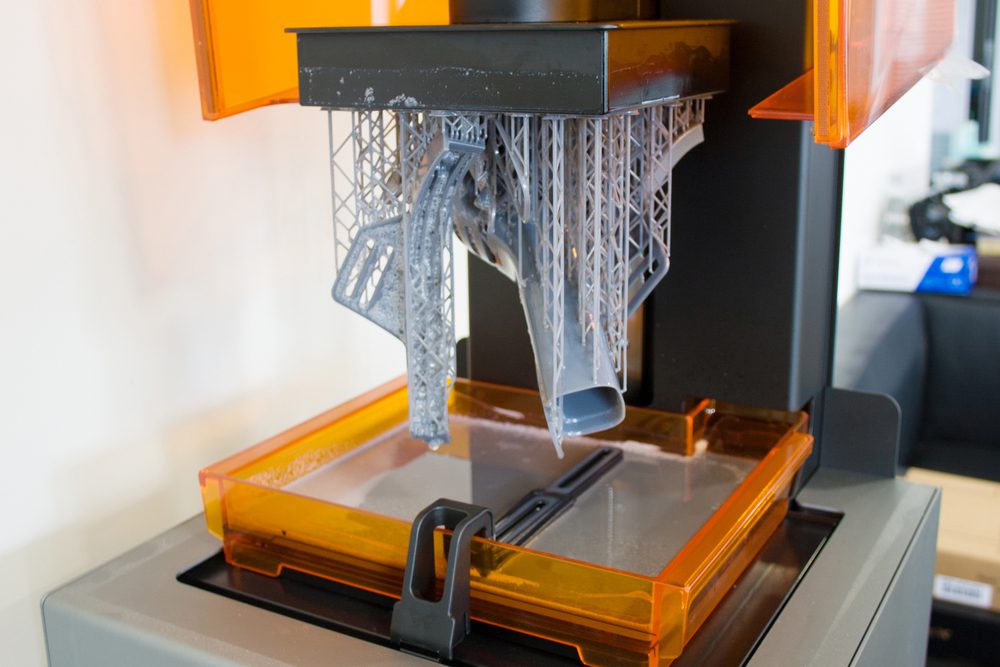

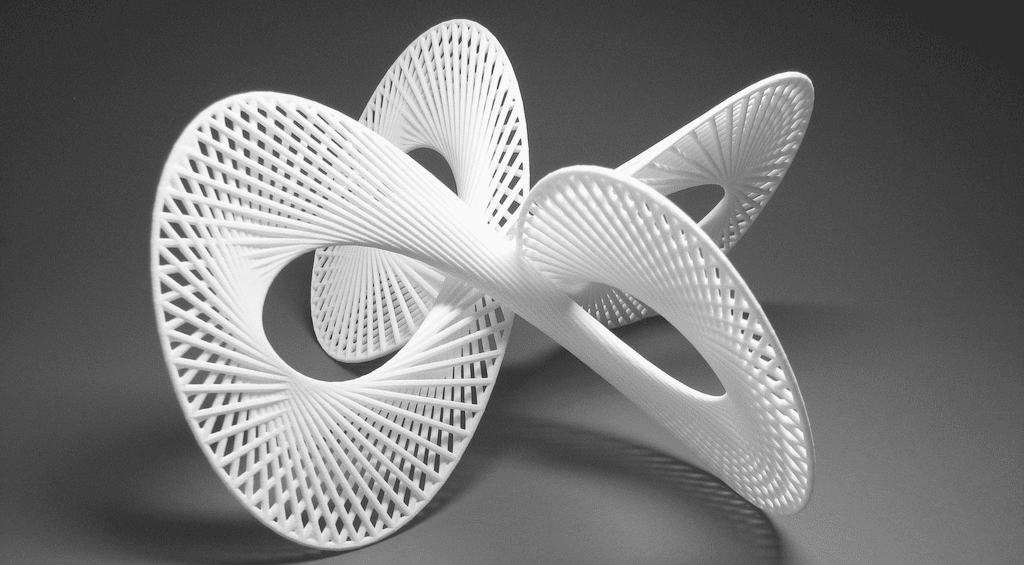

Stereolithography is a 3D printing process that produces parts with a very smooth raw surface.

What is SLA 3D printing?

SLA printing works by solidifying a liquid polymer into the desired form with a special laser. This process is repeated in layers until the part is complete.

Stereolithography is often used to replace traditional injection molding processes, because it creates a very similar part with less time and trouble.

Today, SLA processes are being refined and scaled to fit in different industries and sectors.

SLA 3D printer capabilities

Maximum part size |

Standard lead time |

Tolerance |

Layer height |

Minimum feature size |

| 1380mm x 680mm x 480mm | 20 business days |

200µm |

50µm – 200µm | 1 mm |

SLA 3D printing materials

Compare all our options

Material |

Default Color |

Weaknesses |

Strengths |

Applications |

| SLA High Temp TS | dark blue/navy | limited color options | durable, functional structures | automotive parts |

| SLA Imagine Black | black | slightly weaker than nylon | chemical resistant | chemically resistant parts |

| SLA Proto Plus | white | less durable than other options | highly precise capabilities | consumer medical parts |

| SLA Smooth GP | white | not UV resistant | high performance, waterproof | electronic modification parts |

| SLA Tough Plus | white | easily impressioned | outstanding details | prototype or test parts |

| SLA Tough Resin Green | light yellow/green | unique default color | quick and efficient printing time | end use parts |

| SLA Transparent Plus | transparent | may contain small air bubbles | transparency ability | concept model parts |

| SLA Watertight Proto | white | default color limitations | durable mechanical structures | watertight parts |

Post-processing for SLA

The only post-processing finishing option available for SLA parts is raw. This is because a raw finish with the SLA process is already very smooth and should be acceptable for most projects. We also cannot dye any SLA parts.

If you have any questions about post-processing for SLA parts, please reach out to [email protected].

How SLA stacks up against other 3D printing technologies

Materials |

Price |

Strengths |

Max. part size |

Layer thickness |

Min. feature size |

|

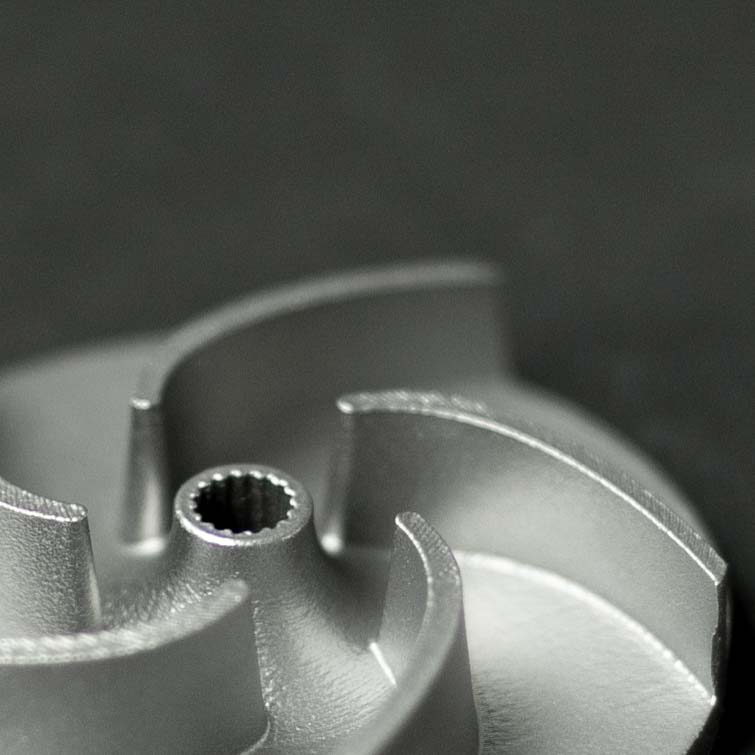

SLM |

Aluminum, 316L Stainless Steel, 17-4 Stainless Steel | $$$ | Metal parts | 400mm x 320mm x 320mm | 50µm – 200µm | 1 mm |

SLA |

Proto Plus, WaterTight, Smooth GP, Transparent Plus, Tough Plus, High Temp TS, Imagine Black | $$ | Smooth surface finish | 1380mm x 680mm x 480mm | 50µm – 200µm | 1 mm |

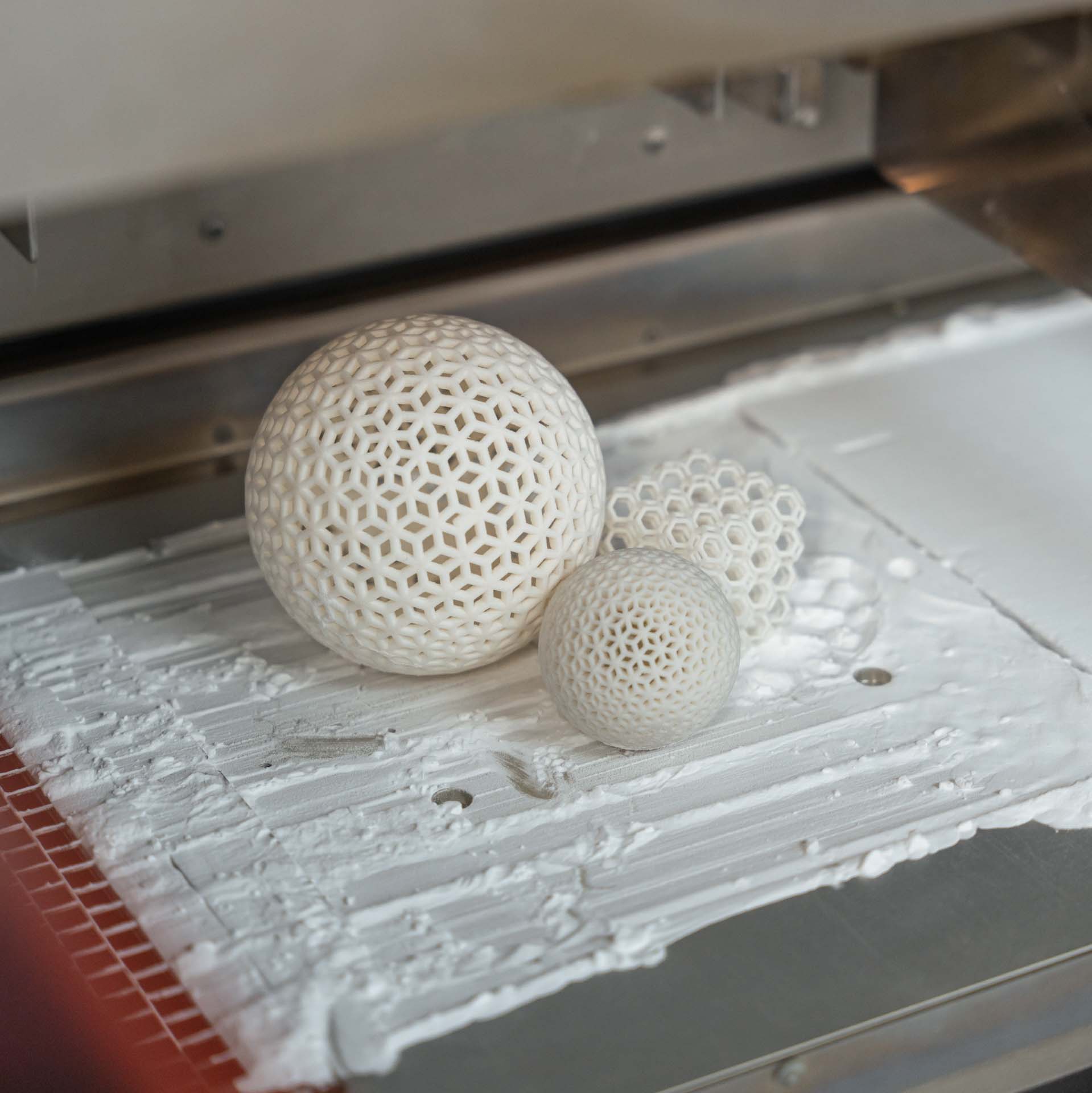

SLS |

Nylon PA12, Nylon PA2200, Thermoplastic Polyurethane (TPU) | $$$$ | High precision |

|

120 µm | 1 mm |

MJF |

Nylon PA12, Nylon PA11, GLass Filled Nylon, Polypropylene, Full Color(CBPA12) | $ | Strong structures | 380mm x 280mm x 380mm | 80 μm | 1 mm |

Why should you choose SLA 3D printing?

SLA printing brings you a high-quality, smooth-surface, and structurally-sound part that will met your needs. Although they can be limited in color options, you can choose from our available natural material colors for your parts.

Read about each SLA material here.

We have high standards for SLA 3D printing

Our JawsTec Standards are top of the line and professional-grade. We promise to deliver your parts quickly and to fulfill your expectations.

Read more about our RMA process, material certifications, and quality requirements here.

Advantages and drawbacks of SLA 3D printing

Advantages

- Structurally reinforced parts

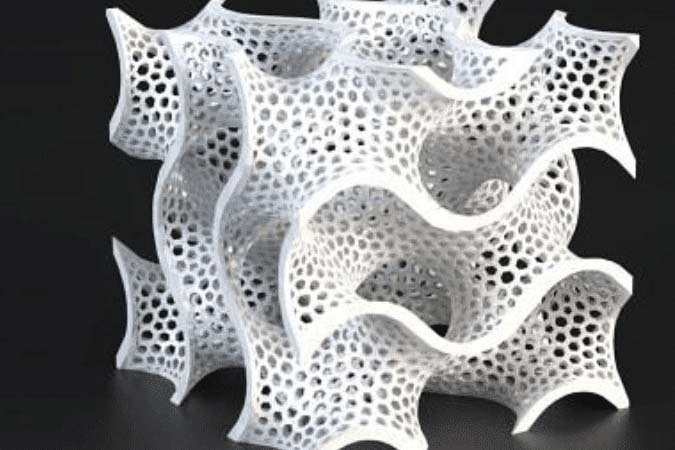

- Highly precise geometries

- Substitute for inject molding

Drawbacks

- Limited color options

- More expensive than nylon printing

- Less suited to mechanically functioning parts

Designing files for SLA printing

When designing CAD files for SLA printing, it is important to remember some requirements for successful designs.

1. Add external support posts that will be needed during printing and can be removed in post-processing

2. Ensure sufficient wall thickness and space between features to minimize warping

3. Text or embossed details should be at least 0.1mm above surface

More resources for 3D printing

Visit the links on the right to learn more about 3D printing! Or, you can visit our blog to explore other helpful articles and information.

Want to learn more about 3d printing?

Our Other 3D printing processes

SLM

Need to print some metal parts? We’ve got you covered with our SLM printing technology.

- Lightweight metal parts

- Highly customizable metal parts

SLS

Looking for another option to print nylon parts? Check out the SLS process

- Dimensional accuracy

- Chemical resistance

MJF

Looking for a cheaper 3D printing option? MJF is the way to go.

- Faster lead times

- Color options