HP 3D High Reusability PA 12 Glass-Beads

HP Jet Fusion 5200/4200 Series 3D Printing Solutions

In addition to HP’s flagship material, HP 3D High Reusability PA 12, HP is growing its portfolio of thermoplastics. Powders such as HP 3D High Reusability PA 12 Glass Beads and HP 3D High Reusability PA 11, deliver optimal mechanical properties. Engineered for HP Multi Jet Fusion technology, these materials test the limits of functional part creation, optimizing cost and part quality, while also delivering high and, in many cases, industry-leading reusability at a low cost per part.

Produce stiff, functional parts

- 40% glass bead-filled thermoplastic material with both optimal mechanical properties and high reusability.

- Provides dimensional stability along with repeatability.

- Ideal for applications requiring high stiffness like enclosures and housings, fixtures and tooling.

Quality at the lowest cost per part

- Produce at a low cost per part and reduce your total cost of ownership.

- Less waste—reuse surplus powder batch after batch and get functional parts, no throwing away anymore.

- Get consistent performance while achieving 70% surplus powder reusability.

- Optimize cost and part quality—cost-efficient material with high surplus powder reusability.1

Engineered for HP Multi Jet Fusion technology

- Designed for production of functional parts across a variety of industries.

- Provides the best balance between performance and reusability.

- Engineered to produce common glass bead applications with detail and dimensional accuracy.

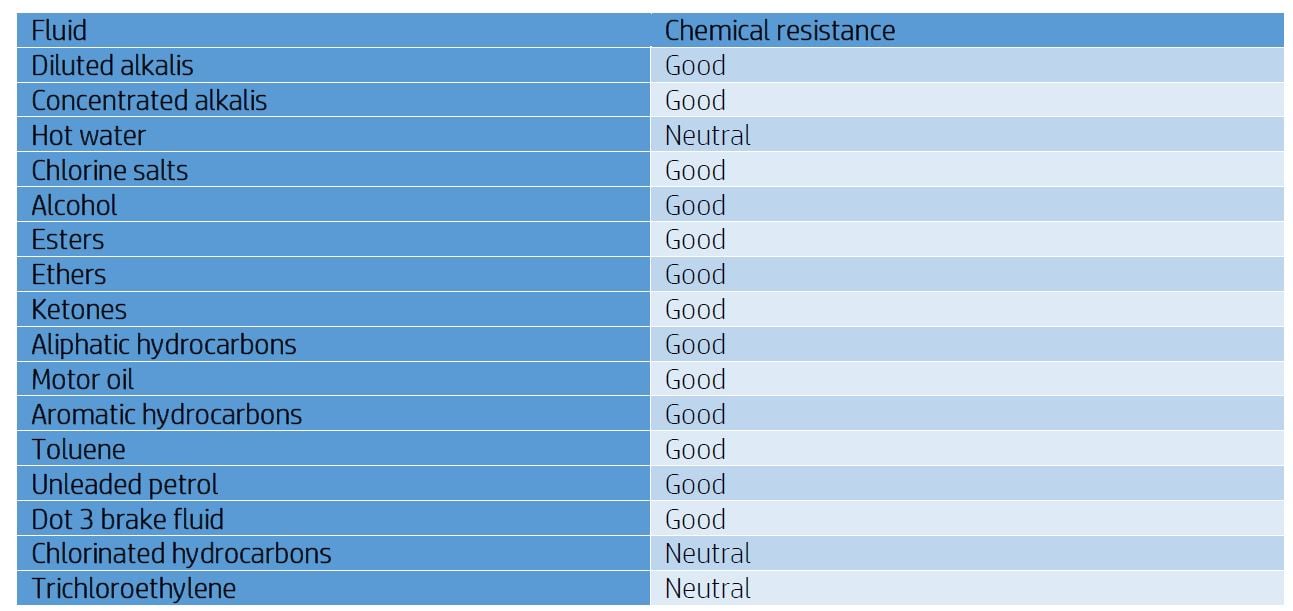

MJF PA12 and MJF PA12 Glass Bead-Fill have a high chemical resistance to a wide variety of commonly-used fluids in the industry.

** Information provided by HP 3D Printing.